What is Drilling

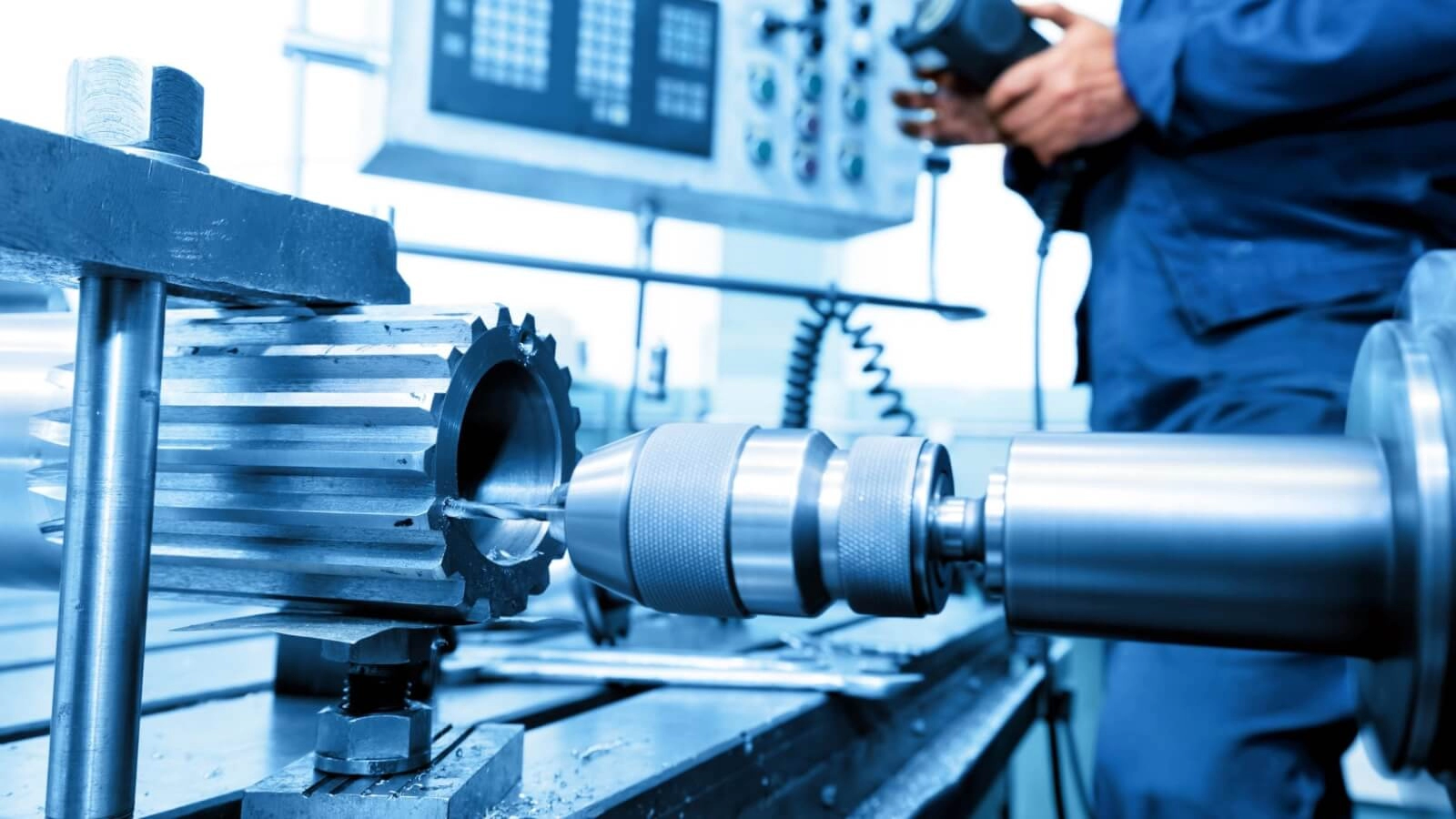

Drilling is the process of creating smooth, clean holes in materials by using a rotating drill bit. Whether you’re working with metal, wood, or plastic, drilling prepares holes for fasteners, assembly, or even aesthetic purposes. The tools involved include various drill bits made from materials like high-speed steel (HSS), cobalt, and carbide, along with CNC drilling machines that boost accuracy and efficiency.

The drilling process uses rotational cutting, often combined with a pecking motion. This pecking helps clear out metal chips and keeps the drill bit cool, preventing overheating and extending tool life.

At TechCNC, our CNC drilling machines stand out by offering precise hole creation with scalable options to fit any project size. With TechCNC, you get consistent quality and faster production, making your drilling tasks more reliable and efficient.

What is Tapping

Tapping is the process of cutting internal threads inside a hole that’s already been drilled. These threads allow screws or bolts to fasten securely, making the joint strong and reliable.

Tools Used for Tapping

- Taps: Including taper, plug, and bottoming taps, designed for different thread depths and applications

- Tap holders: Keep taps aligned and steady during the threading process

- CNC tapping machines: Automate threading with high precision and speed

Applications of Tapping

Tapping is essential in industries where strong, secure fastening is a must. You’ll find it everywhere — from automotive assembly and aerospace parts to heavy machinery and manufacturing lines.

Tapping Process

The process involves carefully cutting internal threads using taps, often with guides to ensure perfect alignment. Cutting fluid is applied to reduce friction, cool the tool, and extend its life, helping create clean, precise threads.

TechCNC Advantage

At TechCNC, our tapping machines deliver high-precision threading that meets the demanding standards of modern manufacturing. Whether it’s for automotive parts or aerospace components, we provide machines designed for accuracy, efficiency, and repeatability.

Drilling vs Tapping A Side-by-Side Comparison

Purpose

Drilling is all about creating clean, smooth holes in a material. Tapping comes after drilling and adds internal threads inside those holes so screws or bolts can grip tightly.

Process Dependency

Drilling stands alone—you can drill holes anytime, anywhere. Tapping needs a hole first, so it relies on the drilling step to prepare the space for threading.

Tools

Drill bits and taps look different and serve distinct purposes. Drill bits come in various sizes and materials like HSS or carbide to cut holes. Taps are designed to carve threads and vary depending on the thread type and material toughness.

Complexity

Drilling tends to be simpler—it’s mostly about speed and chip removal. Tapping requires more care since the threads must align perfectly, or the fastener won’t fit correctly.

Materials

Both drilling and tapping work well on metals and plastics. However, tapping can be trickier on really hard materials because cutting threads needs more precision and proper tools.

| Feature | Drilling | Tapping |

|---|---|---|

| Purpose | Create holes | Cut internal threads |

| Tools | Drill bits (various types) | Taps (taper, plug, bottoming) |

| Speed | Generally faster | Slower due to thread precision |

| Complexity | Lower | Higher, requires precise alignment |

| Material Suitability | Metals, plastics | Metals, plastics (harder metals tougher) |

Understanding these differences helps you decide when and how to use drilling and tapping in your projects for the best results.

When to Use Drilling vs Tapping

Knowing when to drill or tap is key to getting your job done right.

Drilling is your go-to for creating new holes or making existing holes bigger. It’s perfect when you’re prepping materials like metal, wood, or plastic for assembly or fasteners.

Tapping comes into play when you need to add threads inside those pre-drilled holes. This is essential for secure fastening, especially in applications where bolts or screws hold parts tightly together.

Often, you’ll use both together: first, drill the hole, then tap it to cut internal threads. This combo is standard in industries like automotive engine assembly and aerospace, where precision matters for parts like engine blocks and other machinery.

In short, drill to make the hole and tap to make it thread-ready for strong, reliable fasteners.

Tips for Optimizing Drilling and Tapping with CNC Machines

Getting the best results from your CNC drilling and tapping starts with a few smart practices:

- Choose the right tools: Use HSS drill bits and taps for steel, and switch to carbide for tougher materials like titanium. Picking the right tool material makes a big difference.

- Set proper spindle speeds: Run higher speeds for softer materials to speed things up, but slow down for harder metals to avoid tool damage.

- Apply cutting fluid: This keeps temperatures down, reduces friction, and extends the life of your drill bits and taps.

- Use CNC automation: TechCNC machines deliver consistent precision and efficiency, giving you clean cuts and accurate threads every time.

- Practice peck drilling and tapping: Pecking helps clear chips and prevents overheating or tool breakage. It keeps holes clean and threads sharp.

Following these tips will maximize your CNC drilling process and tapping in machining, helping you produce high-quality parts faster and with less downtime.

Why Choose TechCNC for Drilling and Tapping

When it comes to drilling and tapping, TechCNC stands out with advanced CNC machines designed to deliver top-notch accuracy and consistent results every time. Our equipment handles both drilling and tapping processes, making your workflow smoother and more reliable.

We offer custom solutions tailored to industries like automotive, aerospace, and construction. No matter your project size or complexity, TechCNC provides the right tools and setups to meet your production needs.

Plus, our expert team is always ready to help you pick the best tools and optimize your machining process. From selecting drill bits and taps to refining cutting speeds and feeds, we support you every step of the way.

Explore TechCNC’s drilling and tapping machines today or contact us for a personalized quote and take your manufacturing to the next level.